Fan coil units - Heating and cooling with 2 zones

Use case

Your customer will use fan coil units to heat/cool the rooms in the house.

In this example, we assume that 2 zones (rooms) have to be controlled.

In this example, there is 1 fan coil unit in each zone.

Each zone is equipped with a zone valve controlled by a thermostat.

When the zone thermostat requests heating, the fan of the fan coil unit will automatically be set to 60%.

When the zone thermostat requests cooling, the fan of the fan coil unit will automatically be set to 100%.

When no heating or cooling is requested, the fan will automatically be deactivated.

Your customer wants to control the speed of the fan, mounted inside the fan coil units, manually using the Niko Home app:

low (30%)

medium (60%)

high (100%)

boost (100% for 15 minutes , then reduce to 60%)

As a thermostat, you can use a push buttons with LED(s) and comfort sensors or Digital black 24v.

This procedure is based on Niko Home Control programming software version 2.22 or more recent.

Procedure

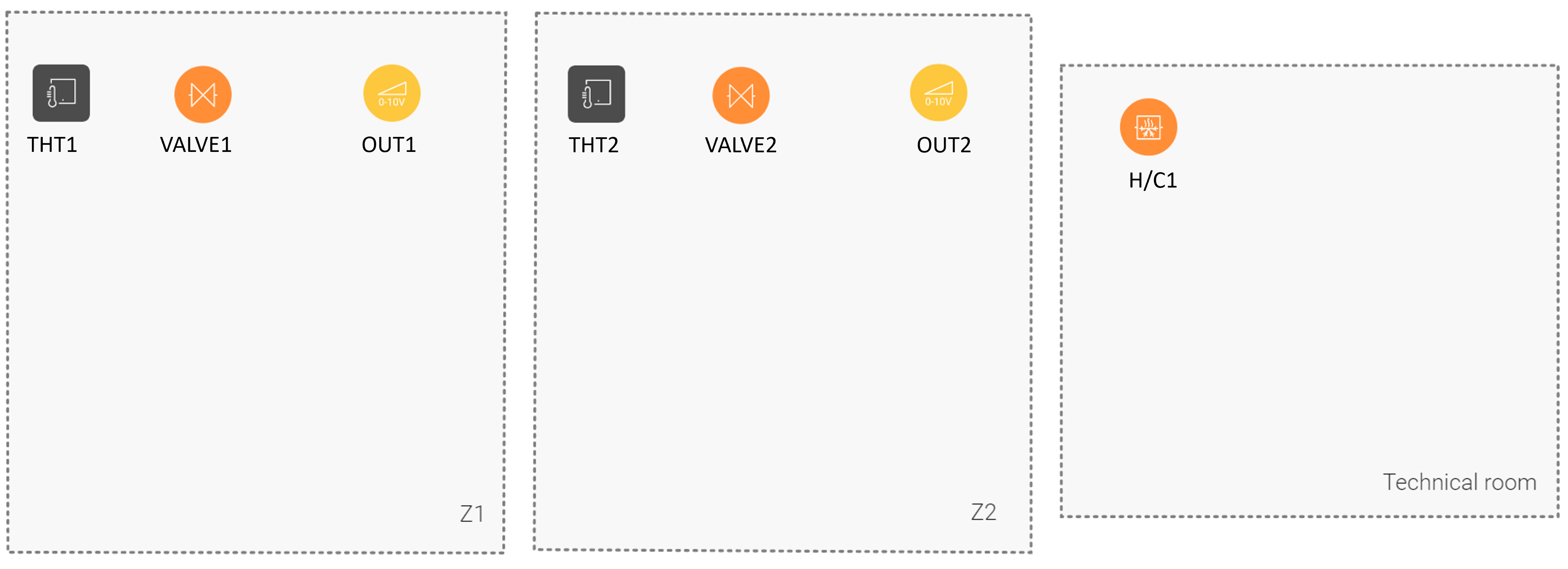

Creating the controls and the devices

Create the thermostats (THT1 and THT2).

Create the zone valves (VALVE1 and VALVE2).

Create a heating system (H/C1).

Create the analogue outputs (OUT1 and OUT2) for controlling the fans.

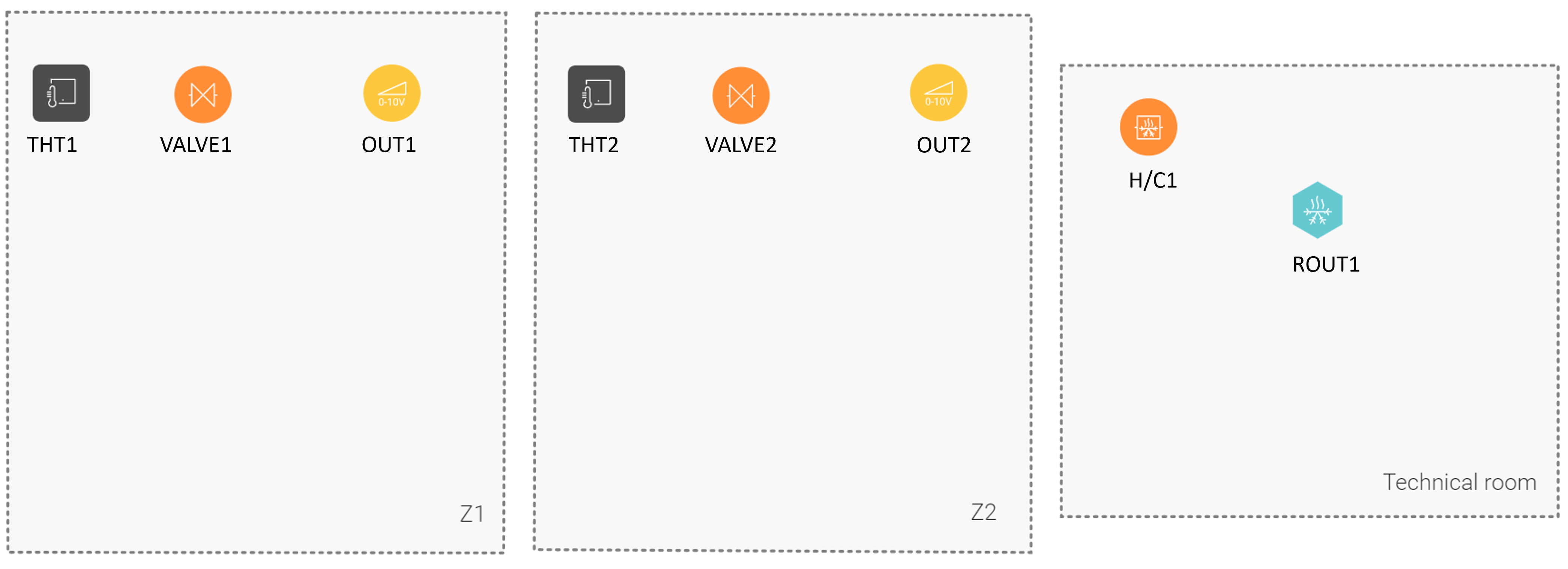

Creating the heating/cooling routine

Create a routine Heating/cooling per circuit (ROUT1). Use the following behaviour:

Select the heating system (H/C1).

Define the heating zones. Combine the correct thermostat with the corresponding zone valve (THT1 and VALVE1, THT2 and VALVE2).

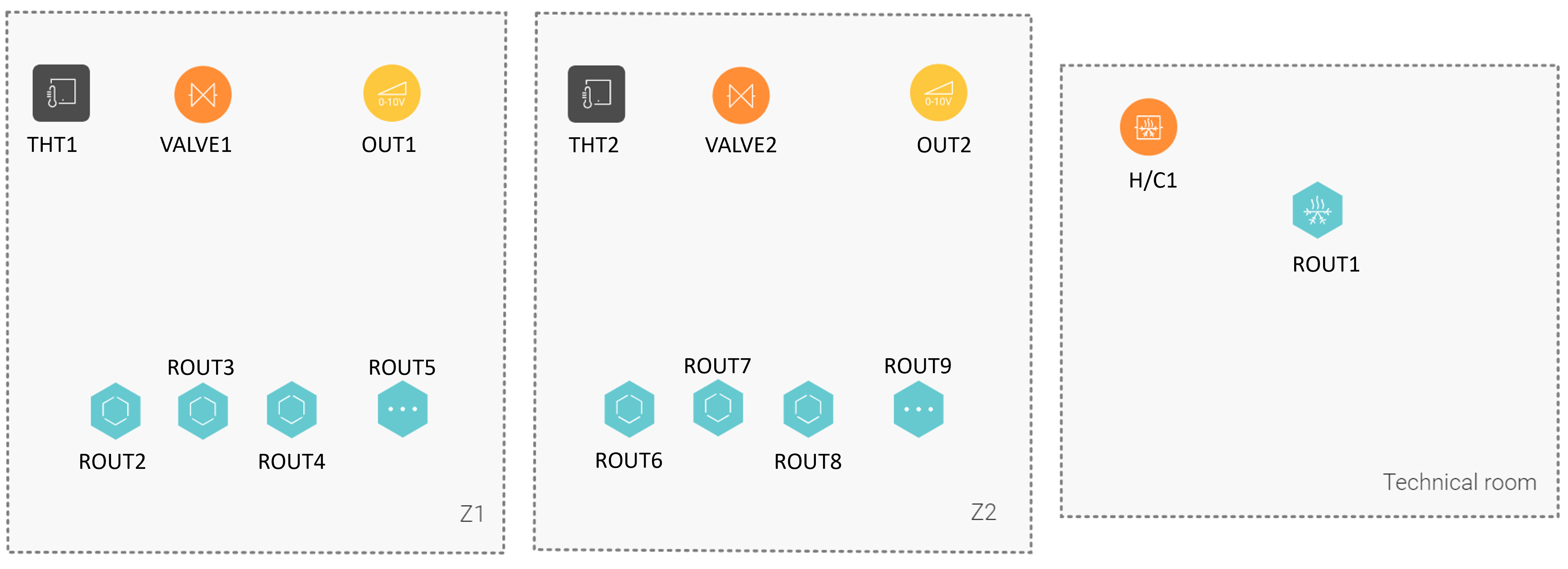

Creating the routines

In Z1,

Create a routine Scene (ROUT2) to define the ventilation speed "low". Use the following behaviour:

Select the device that is part of the routine: analogue output OUT1

Set the parameter level to 30%

Create a routine Scene (ROUT3) to define the ventilation speed "medium". Use the following behaviour:

Select the device that is part of the routine: analogue output OUT1

Set the parameter level to 60%

Create a routine Scene (ROUT4) to define the ventilation speed "high". Use the following behaviour:

Select the device that is part of the routine: analogue output OUT1

Set the parameter level to On

Create a routine Custom routine (ROUT5) to define the ventilation speed "boost". After 15 min the ventilation is set to "medium". Use the following behaviour:

Device that is part of the routine: analogue output OUT1

Start behaviour: OUT1: Level = On, Dimming Time = 1 s, Delay = 0 s

Stop behaviour: OUT1: Level = 60%, Dimming Time = 1 s, Delay = 0 s

Check "Stop this routine automatically..." and set the time period to 15 min

In Z2 follow the steps described above but use the data in the table below.

Type of routine | In Z2 |

|---|---|

Scene | ROUT6, ROUT7 and ROUT8 with OUT2 |

Custom routine | ROUT9 with OUT2 |

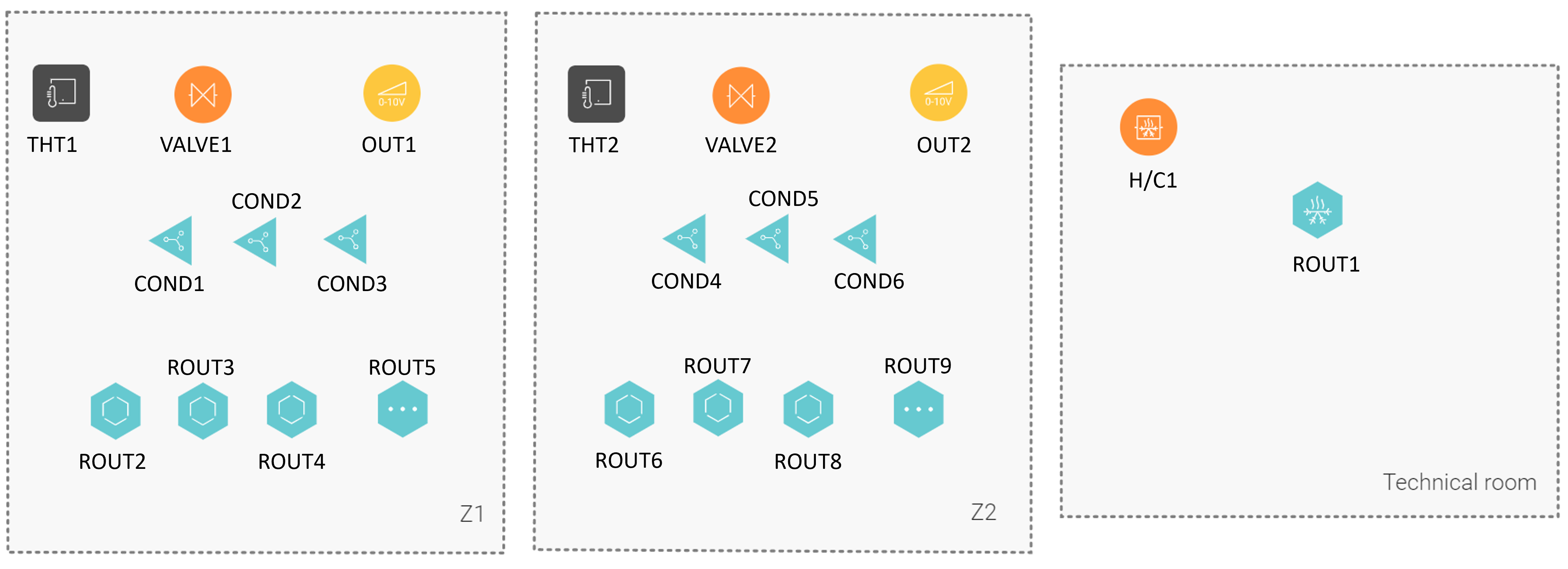

Creating the conditions

If heating/cooling is required in a zone, then 230 V is applied to the zone valve, the fans are unlocked and the ventilation speed is set to 60% for heating and 100% for cooling.

If heating/cooling is no longer required in a zone, then 230 V is no longer applied to the zone valve, and the fans are stopped and locked.

In Z1,

1. Create a condition (COND1) for controlling the fans when heating is required. Use the following logic:

IF VALVE1= Open and ROUT1: State = Heating mode active

THEN

OUT1: Level = Unlock, Delay = 0 s

OUT1: Level = 60%, Dimming Time = 1 s, Delay = 0,1 sELSE Leave empty

2. Create a condition (COND2) for controlling the fans when cooling is required. Use the following logic:

IF VALVE1 = Open and ROUT1: State = Cooling mode active

THEN

OUT1: Level = Unlock, Delay = 0 s

OUT1: Level = On, Dimming Time = 1 s, Delay = 0,1 sELSE Leave empty

3. Create a condition (COND3) for controlling the fans when heating/cooling is no longer required. Use the following logic:

IF VALVE1= Closed

THEN

OUT1: Level = Off, Dimming Time = 1 s, Delay = 0 s

OUT1: Level = Lock, Delay = 0,1 sELSE Leave empty

In Z2 follow the steps described above to create the following conditions:

Filling the cabinet and addressing the devices

You can assign a maximum of four zone valves on a heating or cooling module 4U.

Contact 5 of that module is a demand contact or an H/C contact.

Fill the cabinet with ... | and address the following devices ... |

|---|---|

a heating or cooling module 4U (MOD1) |

|

an analogue control module 0 - 10 V 2U (MOD2) | the analog outputs OUT1 and OUT2. |

a switching module (3x) 2U (MOD3) |

. |

(*) This contact closes when one of the thermostats demands heating and opens when it demands cooling. Depending on how the heating/ cooling system is designed, this contact may not need to be connected to that system.

(**) This contact closes when one of the thermostats is in 'demand' and opens when no thermostats are in 'demand'. Depending on how the heating/ cooling system is designed, this contact may not need to be connected to the heating/ cooling system.

Example

Click here to download the programming example.

(FPE_027_222_1.nhc2 file).

Wiring diagram